Monocrystalline silicon bivuga muri rusange kristalisation yibikoresho bya silikoni muburyo bumwe bwa kirisiti, kuri ubu ikoreshwa cyane mubikoresho bitanga ingufu za fotovoltaque, selile yizuba ya monocrystalline niyo tekinoroji ikuze cyane mumirasire y'izuba ishingiye kuri silicon, ugereranije na polysilicon na amorphous silicon izuba, imikorere yayo yo guhinduranya ifoto ni nini cyane. Umusaruro wa selile nziza ya monocrystalline silicon ushingiye kubikoresho byiza bya monocrystalline silicon nibikoresho byiza bya tekinoroji ikuze.

Imirasire y'izuba ya Monocrystalline ikoresha inkoni ya monocrystalline silicon ifite ubuziranenge bugera kuri 99,999% nk'ibikoresho fatizo, nabyo byongera igiciro kandi bigoye gukoresha ku rugero runini. Mu rwego rwo kuzigama ibiciro, ibyangombwa bisabwa kugirango ikoreshwa ryizuba rya monocrystalline silicon izuba ryorohewe, kandi bamwe muribo bakoresha ibikoresho byumutwe numurizo bitunganyirizwa nibikoresho bya semiconductor hamwe n ibikoresho bya silikoni ya monocrystalline, cyangwa bikozwe mumashanyarazi ya monocrystalline. Tekinoroji yo gusya monocrystalline silicon wafer ni uburyo bwiza bwo kugabanya gutakaza urumuri no kunoza imikorere ya bateri.

Mu rwego rwo kugabanya ibiciro by’umusaruro, ingirabuzimafatizo zikomoka ku zuba hamwe n’ibindi bikorwa bishingiye ku butaka bifashisha inkoni ya silikoni yo mu rwego rwa monocrystalline, kandi ibipimo ngenderwaho byakozwe byoroheje. Bamwe barashobora kandi gukoresha ibikoresho byumutwe numurizo hamwe nibikoresho bya silikoni ya monocrystalline itunganywa nibikoresho bya semiconductor kugirango bakore inkoni ya silikoni ya monocrystalline. Inkoni ya monocrystalline ya silicon yaciwe mo ibice, muri rusange uburebure bwa mm 0.3. Nyuma yo gusya, gusukura nibindi bikorwa, wafer ya silicon ikozwe mubintu fatizo bya silicon wafer kugirango bitunganyirizwe.

Gutunganya imirasire y'izuba, mbere ya byose kuri silicon wafer doping no gukwirakwizwa, doping rusange kumubare wa boron, fosifore, antimoni nibindi. Diffusion ikorerwa mu itanura ryubushyuhe bwo hejuru ikozwe muri quartz. Ibi birema P> N ihuriro kuri silicon wafer. Noneho uburyo bwo gucapa bwa ecran burakoreshwa, paste nziza ya feza icapishwa kuri chip ya silicon kugirango ikore umurongo wa gride, hanyuma nyuma yo gucumura, electrode yinyuma irakozwe, kandi hejuru yumurongo wa gride wasizwe hamwe nisoko yo kumurika kugirango wirinde umubare munini wa fotone kutagaragara hejuru ya chip ya silicon.

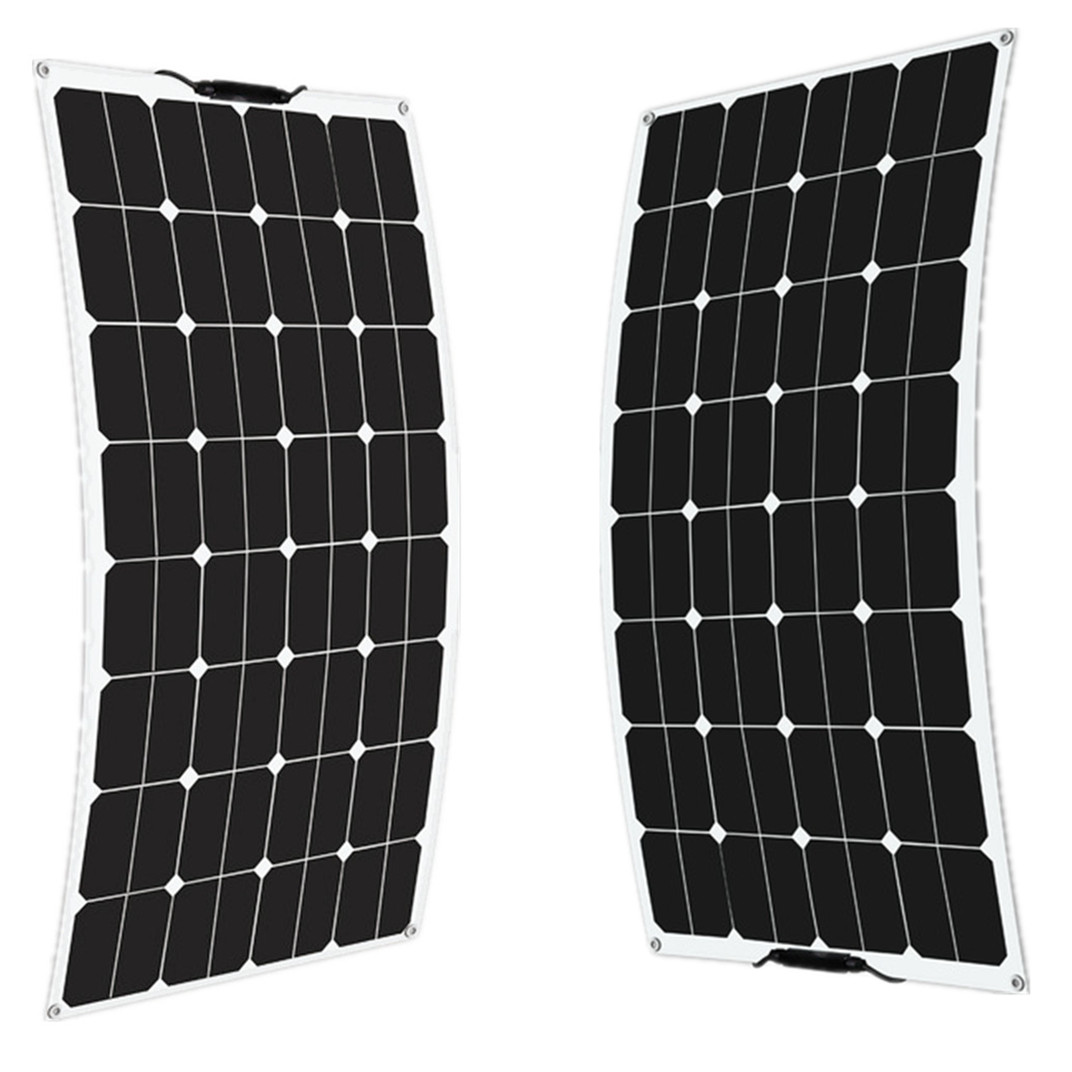

Rero, urupapuro rumwe rwa monocrystalline silicon izuba ryakozwe. Nyuma yubugenzuzi butunguranye, igice kimwe gishobora gukusanyirizwa mumirasire y'izuba (panneaux solaire) ukurikije ibisobanuro bisabwa, kandi ingufu zimwe na zimwe zisohoka n’umuyaga bigizwe nurukurikirane hamwe nuburyo bubangikanye. Hanyuma, ikadiri nibikoresho bikoreshwa mugukurikirana. Ukurikije igishushanyo mbonera cya sisitemu, uyikoresha arashobora guhimba imirasire yizuba muburyo butandukanye bwubunini butandukanye bwizuba, bizwi kandi nkizuba. Ihinduka rya fotoelectric ya selile yizuba ya monocrystalline silicon ni hafi 15%, naho ibisubizo bya laboratoire birenga 20%.

Igihe cyo kohereza: Nzeri-07-2023